Many Master Bond epoxy systems are formulated with superior chemical resistance. In the lab, we continually test our materials by exposing them to specific chemicals over a long period of time. A common way of testing the chemical compatibility of an epoxy is immersing a sample in a chemical and measuring its change in weight over time. A significant loss or gain in weight would indicate a decreased ability of a material to stand up to chemical exposure. These tests allow us to more accurately recommend the right adhesive based on specific application requirements.

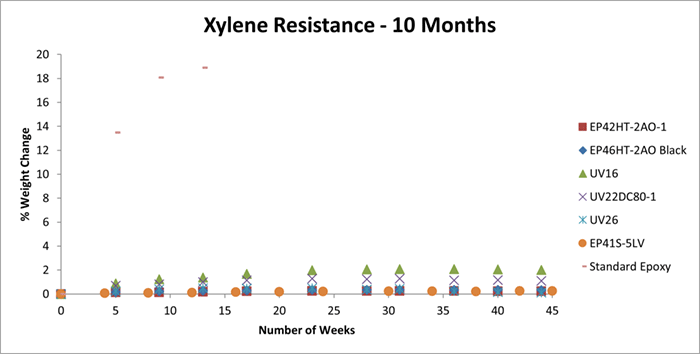

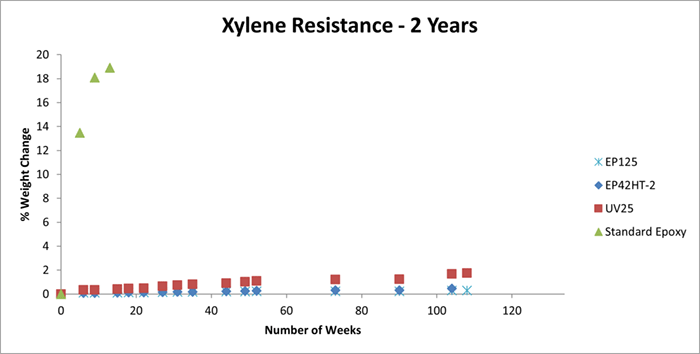

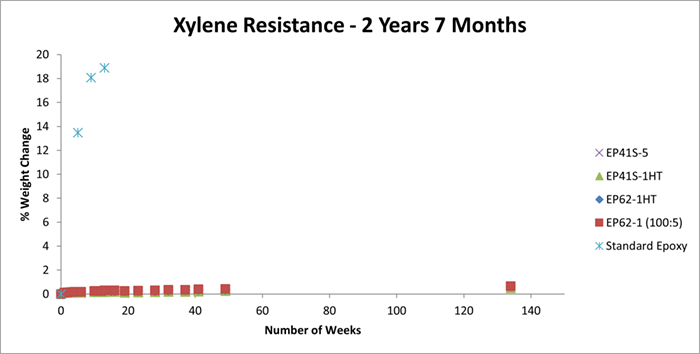

In this experiment, we focused on testing our epoxies for their resistance to xylene. The compounds Master Bond used for testing are a variety of two component epoxies and one component UV curing systems with good overall chemical resistance. For the first round of testing the products tested were EP41S-5LV, EP42HT-2AO-1, EP46HT-2AO Black, UV16, UV22DC80-1, and UV26. For the second round of testing the products tested were EP125, EP42HT-2 and UV25. For the final round the products tested were EP41S-5, EP41S-1HT, EP62-1HT and EP62-1. These were compared against the resistance of a generic or standard non-chemically resistant epoxy. A few thin castings, roughly 2 inches in diameter and around 0.125 inches thick, were made for each product and cured in accordance to their specifications. Once the cured samples were created and initial weight was recorded, we submerged them in xylene. Then we continued recording weekly weight measurements. We carried on these tests with frequent weight recording for varying lengths of time based on the products performance. Below you will see the results for soaking results for around 10 months in the first batch, 2 years for the next batch, and greater than 2.5 years for the third batch of products. The castings were weighed periodically and the graphs shown below demonstrate the percentage of weight change over time.

For the purpose of comparison, please notice that for each testing timeframe, a casting of a standard epoxy was also tested under these same conditions which served as a reference. As can be seen in the graphs, the standard epoxy was not as resistant to xylene as the other epoxies tested. It demonstrated a significantly greater change in weight over time, and the casting ultimately dissolved in xylene after 15 weeks.

In general, a swelling of less than 4-5% can be considered excellent, especially since this test may be more rigorous compared to actual service conditions. It is also worth noting that in the context of a bonded joint or a potted assembly the exposure to xylene might not be as severe or direct as in the above test conditions.

Please note, when choosing an epoxy for an application where the resistance to xylene is critical, many other factors must be considered in addition to the chemical resistance. Each of the epoxies in the charts above offers a distinct set of performance properties. For example, if thermal conductivity and high temperature resistance are needed, EP46HT-2AO Black may be a good option. If a fast cure is required and there is full access to a light source with no shadows, UV26 can be considered. For longer term exposure to xylene over several months to a year or longer, the likes of UV25, EP125 EP41S-5, and EP62-1 are excellent candidates. They all need to be processed or cured differently and although some of them can be cured at room temperature alone, for enhancing/optimizing chemical resistance especially to xylene, it is critical to add heat.

Disclaimer: The findings in this article are not meant to be used for specification purposes.

Compounds Resistant To Xylene

|

EP41S-5LV Excellent chemical resistance to solvents, alcohols, fuels, acids and bases. Low viscosity with good flow properties. Can be used for potting/encapsulation. Formidable physical strength properties. Serviceable from -80°F to +350°F. |

|

EP42HT-2AO-1 Black Good heat conduction. Serviceable from 4K to +400°F. Resists water, oils, fuels. Excellent dielectric properties. Enhanced dimensional stability. Castable up to 2-3 inches thick. Low shrinkage upon cure. Good flow. Meets NASA low outgassing standards. |

|

EP46HT-2AO Black Thermally conductive/electrically insulative. Passes NASA low outgassing tests. Serviceable from -100°F to +500°F. Tg 200-210°C. Remarkable dimensional stability. Impressive mechanical strength properties. |

|

UV16 Superior chemical resistance and physical strength properties. Low shrinkage after cure. Passes NASA low outgassing tests. Excellent thermal stability. Cationic curing system. Outstanding optical clarity. Easy to apply. Low viscosity. Serviceable from -80°F to +400°F. |

|

UV22DC80-1 Dual cure system with UV and heat curing mechanisms. Cures at 80°C in shadowed out areas. Nano filled, high dimensional stability and abrasion resistance. Bonds well to metals, glass, ceramics and most plastics. Serviceable from -60°F to +350°F. |

|

UV26 Specialty type UV curable adhesive with very fast curing time and high thermal stability. Its glass transition temperature is 160 to 170°C and its service temperature range is -60°F to +500°F. UV26 resists acids, bases, fuels, and many aggressive solvents. |

|

EP125 Structural epoxy adhesive resists temperatures up to 500°F. Exceptional durability and flexural strength. High adhesion to metallic and non-metallic substrates. Heat curable system. Tg +240°C. Special two part epoxy with very long working life. Excellent compressive strength. Service operating temperature range from -80°F to +600°F. |

|

EP42HT-2 Bonding, sealing, coating, potting compound. Heat, chemical, steam resistant. Superior optical transmission properties. Solvent free. Withstands exposure to acids, alkalis and many solvents. Castable up to 2-3 inches. Cures readily at ambient temperature. Service temperature range -60°F to +450°F. |

|

UV25 Multi-purpose, one part UV curing system for bonding, sealing, coating and encapsulation. Excellent optical clarity, superb physical properties, moderate viscosity. Ultra high glass transition temperature (Tg) over 180°C. Fast fixture times. Rapid curing. Serviceable from -60°F to +500°F. |

|

EP62-1HT Superior resistance to harsh chemicals, particularly to acids. Two part epoxy has long pot life at ambient temperatures. High bond strength properties. Ideal for bonding and coating. Good flow. Reliable electrical insulator. Serviceable from -60°F to +450°F. Tg 150-160°C. Shore D hardness 80-90. |