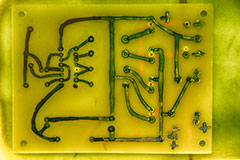

Select Master Bond sealants and potting compounds have been formulated to protect electronic circuits within various sized enclosures from ingress from water, salt water, rain, ice, sleet, snow, aggressive chemicals/vapors such as solvents, acids, coolants, cleaning detergents etc. These compositions consist of epoxies, silicones, hybrid epoxy polyurethane systems and are designed to withstand temperature variations without deterioration, cracking or deformation. In addition to their extraordinary leak protection characteristics these compositions exhibit superior long term electrical insulation properties even upon exposure to harsh conditions. This allows safe, reliable performance without equipment malfunctions for both industrial/consumer applications. Low viscosity systems have been successfully employed for use in high density assemblies.

Select Master Bond sealants and potting compounds have been formulated to protect electronic circuits within various sized enclosures from ingress from water, salt water, rain, ice, sleet, snow, aggressive chemicals/vapors such as solvents, acids, coolants, cleaning detergents etc. These compositions consist of epoxies, silicones, hybrid epoxy polyurethane systems and are designed to withstand temperature variations without deterioration, cracking or deformation. In addition to their extraordinary leak protection characteristics these compositions exhibit superior long term electrical insulation properties even upon exposure to harsh conditions. This allows safe, reliable performance without equipment malfunctions for both industrial/consumer applications. Low viscosity systems have been successfully employed for use in high density assemblies.

Low shrinkage, solvent free (Low VOC) corrosion resistant compounds are available in a range of hardnesses. Value added silicone grades feature high/low temperature serviceability, elasticity and stress relief.

Master Bond EP30-2 was used in a research article at the University of Colorado Boulder for an electrowetting lens application. Here is a quote from this paper: “The substrate is bonded to the cylinder using Master Bond EP30-2 in order to ensure a leak-proof enclosure that resists liquid permeation and isolates the substrate electrode from the sidewall electrode.”1

Sources:

1https://ecee.colorado.edu/~julietg/Papers/2015_Watson_EWODlenses.pdf. Alexander M. Watson, Kevin Dease, Soraya Terrab, Christopher Roath, Juliet T. Gopinath, Victor M. Bright. Focus-tunable low-power electrowetting lenses with thin parylene films. Applied Optics 4 Vol. 54, No. 20. July 8, 2015. Accessed June 2016.

[1]