Expanded Product List

Master Bond Product Search

139 products match

|

MB297Med-3 High bond strength. Rapid fixture time. Ultra low viscosity 10-20 cps. USP Class VI approved. For disposable and reusable medical devices. Serviceable from -60°F to +250°F. |

|

MB306 Low viscosity methyl cyanoacrylate with superior bonding properties especially to metals. Contact pressure usually sufficient for fixturing. Viscosity 75-95 cps. Shore D hardness 70. Fast curing. Serviceable from -60°F to +250°F. |

|

MB350 Low viscosity alkoxyethyl cyanoacrylate. High strength, rapid curing. Low odor, low bloom system. No mixing or heating needed. Good resistance to cleaning agents. Serviceable from -60°F to +250°F. |

|

MB600 Environmentally safe, water soluble, one part system. Thermal stability up to +1,500°F. Outstanding strength, dimensional stability and electrical insulation properties. Completely odorless, non-toxic and non-flammable. Cures obtained at moderately elevated temperatures. |

|

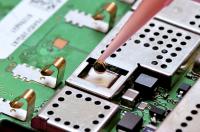

Super Gel 9 Two part, room temperature curing, epoxy gel compound for sealing and encapsulation. Optically clear, soft and dimensionally stable. Ideal for retrievability. Two to one mix ratio by weight or volume. Low exotherm. Long working life. Low viscosity system. Unsurpassed thermal cycling and mechanical shock resistance. Used in conjunction with sensitive electronic and optical components. Serviceable from -100°F to +200°F. |

|

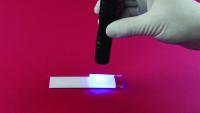

UV10 One component, no mix, UV curable adhesive. High strength bonds and superior chemical resistance properties. Low viscosity. Excellent dimensional stability. Fast curing. Serviceable from -60°F to +300°F. |

|

UV10-FD One component, UV curable adhesive contains a flourescent dye for identification. High strength bonds and superior chemical resistance properties. Low viscosity. Excellent dimensional stability. Fast curing. Serviceable from -60°F to +300°F. |

|

UV10LV Exceptionally low viscosity. Fast curing. Outstanding dimensional stability and electrical insulation properties. Superior optical clarity. Chemical resistant. Ideal for spin coating. Excellent adhesion to surface treated metals, glass, plastics including polycarbonates and acrylics. Serviceable from -60°F to +250°F. |

|

UV10Med USP Class VI approved, optically clear adhesive. Fast curing. Resists many chemicals and sterilants. Electrically insulative. High bond strength to metals, glass, plastics such as polycarbonates, acrylics. Serviceable from -60°F to +250°F. |

|

UV10TK Single component, moderate viscosity UV curable system. Outstanding optical clarity. Enhanced chemical and temperature resistance. Exceptional dimensional stability. Easy application. Serviceable from -60°F to +300°F. |