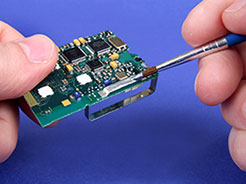

Conductive bonding agents play a fundamental role in ensuring reliable electrical connectivity in many electromechanical assemblies designed to operate at the extremes of temperature and pressure of space. Failure of a single bond between conductive components in an assembly can ripple rapidly through mechanical and electrical systems, ultimately threatening spacecraft integrity and crew safety. In two applications, Master Bond EP21TDCS-LO conductive epoxy met critical requirements for maintaining robust bonds in electromechanical systems intended to operate in space conditions.

Master Bond Polymer System EP21TDCS-LO is a two component, silver-filled epoxy designed to ensure high-strength conductive bonds between dissimilar materials at temperatures down to 4K. Unlike most two-part silver-filled adhesives, Master Bond EP21TDCS-LO uses a simple one-to-one mix ratio that remains workable for 30-40 minutes and cures at room temperature in 24-48 hours or in 1-2 hours at 200°F. With volume resistivity less than 10-3 ohm-cm, this adhesive cures to an electrically conductive bond that combines high strength (shear strength over 850 psi) and flexibility (T-peel strength over 5 pounds per linear inch) – properties unusual in a silver epoxy. Along with its workability and performance characteristics, Master Bond EP21TDCS-LO meets critical requirements for space operations including passing NASA low-outgassing test criteria.

The applications listed in the table below highlight use of Master Bond EP21TDCS-LO in ensuring high-strength, conductive bonds in assemblies designed to survive the harsh conditions of space.

Applications of Master Bond EP21TDCS-LO

| Industry | Application | EP21TDCS-LO Role | Critical Properties |

| Aerospace | Creating a space-like test environment for studying electrostatic discharge (ESD) effects on spacecraft1 | Bonding samples for extended ESD testing at low temperature and pressure | Ease of use Bond conductivity and durability in high electric fields Non-reactive, no volatiles, NASA-outgassing compliant |

| Aerospace | Studying properties of an electrohydrodynamic (EHD) pump2 | Bonding electrodes needed to generate electric fields for EHD | Ease of use for bonding dissimilar materials Bond conductivity and durability through extended mechanical, thermal, and electrical stress Non-reactive, no volatiles, NASA-outgassing compliant |

Sources

1Dekany, Justin; Johnson, Robert H.; Wilson, Gregory; Evans, Amberly; and Dennison, JR, "Ultrahigh Vacuum Cryostat System for Extended Low Temperature Space Environment Testing," All Physics Faculty Publications, Paper 1455, 2012.

2Sinnamon, Samuel, “Coolant Distribution Control in Satellite Structural Panels Using Electrohydrodynamic Conduction Pumping,” MS thesis, Mechanical Engineering, University of New Mexico, May 2012.